3D

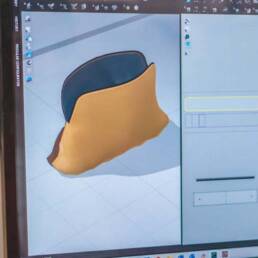

3D and 2D drawings

We design with fully integrated 2D and 3D CAD software and through hi-tech material textures we can create realistic product images that are almost impossible to distinguish from a still life picture.

PBR Texture

Physical Based Rendering technology consists of “photographing” materials with special scanners that detect every material’s physical feature: depth, reflections, nuances, etc. That’s how we can make realistic 3D images.

3D

3D and 2D drawings

We design with fully integrated 2D and 3D CAD software and through hi-tech material textures we can create realistic product images that are almost impossible to distinguish from a still life picture.

PBR Texture

Physical Based Rendering technology consists of “photographing” materials with special scanners that detect every material’s physical feature: depth, reflections, nuances, etc. That’s how we can make realistic 3D images.

PRODUCTION TECHNOLOGIES

The perfect human hands

Repetitive work, as well as the most difficult and risky ones, can be carried out by sophisticated machines, which are much more precise than the human hand.

As a result, while in the workshops increasingly perfect products are made, the craftsman engages in higher tasks, like the development of new products and techniques. Here are two examples.

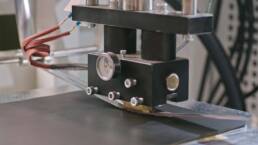

Computerised automatic cutting (CAM)

The machine in our workshop, pictured besides, can cut every pattern made through our CAD software, with a precision of 0,1 millimetre and can optimise the positioning of patterns to get the most out of every inch of material.

Swing-arm sewing machines

The swing-arm sewing machine, can stitch at the farer corners whatever complex the shape of a bag, with the highest precision and without smearing.

ORGANISATION

Continuous improvement and a constant search for excellence are at the heart of innovation. Corium Line, in its laboratory of over 1,500 sq.m. dedicated to product design and prototyping, adopts an advanced ERP software for operations management, computerised machines (CAM), networked 2D and 3D design software and proprietary operational model.

ORGANISATION

Continuous improvement and a constant search for excellence are at the heart of innovation. Corium Line, in its laboratory of over 1,500 sq.m. dedicated to product design and prototyping, adopts an advanced ERP software for operations management, computerised machines (CAM), networked 2D and 3D design software and proprietary operational model.

Our functional areas are:

- Design and industrialisation of styles (models)

- Product development and materials research office

- Purchasing office

- Planning and production management

- Materials and finished product warehouse

- Finished products quality control area

- Packaging and shipping

- Administration and finance

- Executives and managers

Service

In the complex world of production and trade, there is always room for exceptions, whether it is an after sales, an urgent production or a special order.

For every exception, we have only one rule: service

CORIUM LINE

Our business is to design and manufacture leather goods.

We have been doing this for more than twenty years.

The design and interpretation of a product are the essence of leather goods. Over the years, Corium Line has built up a solid design capacity, recognised by the most important and demanding brands. Continuous investments in the acquisition of the best design technologies allow us to satisfy even the most sophisticated ideas, within the tight timescale of fashion.

The automatic machines Corium Line is endowed with, carry out the most critical manufacturing phases from cutting to stitching, through micro-processes such as the skiving or splitting of hides, with extreme precision and speed.

Large production volumes are subcontracted to external trusted partners. Alongside core activities, many other specialised functions revolve, such as research and procurement of materials, production planning and finished product QC, all of them linked and coordinated thru an integrated ERP software.

FOREIGN PRODUCTION

In addition to the production carried out entirely in our facilities in Italy, we are organized to offer our customers who request it, the possibility of producing the items in Eastern European countries and in China, where for years we have established collaborations with leather factories that can meet the different demands that the customer requires of us.

MATERIALS PROCESSES AND ENVIRONMENT

Strengthened environmental awareness, continuous research and new technologies have brought new and extraordinary materials to the market.

Corium Line has a historical ability and experience in using these uncommon products such as technical textiles, low-CFC polymers, mesh, and nickel-free metals.

Corium Line also adopts an air processing and cleaning system throughout the laboratory to ensure the highest quality working environment; it also complies with all Italian safety regulations.

MATERIALS, PROCESSES AND THE ENVIRONMENT

Increased environmental awareness, continuous research and new material technologies have brought about new and extraordinary materials.

Corium Line has a long-standing ability and experience in using uncommon materials such as technical textiles, low CFC polymers, knits, nickel-free metals and other materials.

Corium Line also adopt a workshop-wide air cleaning and extraction system, to assure the highest quality of the working environment, and comply with all Italian health and safety legislations.

Increased environmental awareness, continuous research and new material technologies have brought about new and extraordinary materials.

Corium Line has a long-standing ability and experience in using uncommon materials such as technical textiles, low CFC polymers, knits, nickel-free metals and other materials.

Corium Line also adopt a workshop-wide air cleaning and extraction system, to assure the highest quality of the working environment, and comply with all Italian health and safety legislations.

SUSTAINABILITY

Our commitment to sustainability is reflected in the traceability of raw materials used.

All materials have traceability certifications specifying origin and quality; we normally prefer “green” materials to meet the growing demand for sustainability in the fashion industry.

We use the utmost care and attention in our production processes to offer environmentally friendly and sustainable products to our customers.